ENGLISH

-

Home

-

About

About

Deep in the field of passenger car suspension system for several years, through independent innovation. In the field of passenger car AIR SPRING manufacturing is at an advanced level, the number of air spring production lines manufactured in the forefront of the domestic...

MORE

-

Products

Products

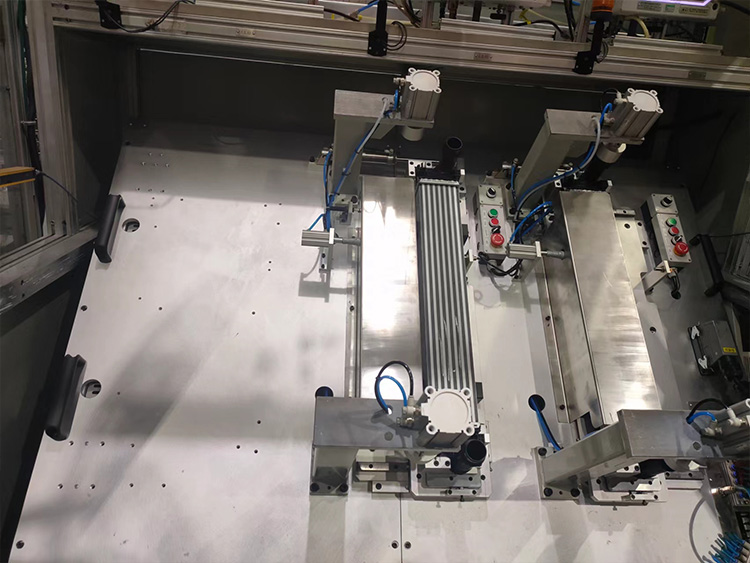

Our company has more than 150 employees, with R & D department and engineer technicians accounted for 70%. Our factory area has more than 8,000 square meters, with a complete non-standard automation independent development and manufacturing capabilities...

Automotive chassis suspension system Automotive caliper braking system Automotive steering system Automotive air conditioning system

-

Customer

Customer

We adhere to people-oriented, create value for customers, create the future for employees. We adhere to service first, to professional, intimate service to give customers a comfortable experience.

-

Service

Service

We adhere to customer-oriented, consumer-oriented. To customer's success and meet the needs of consumers is the value of our enterprise. Service creates value, service wins respect, service builds brand.

-

News

News

You can learn about the new trends of HMD in real time, share the lastest information of the industry with you, and serve you at all times.

-

HR

HR

We adhere to people-oriented, create value for customers, create the future for employees. We adhere to service first, to professional, intimate service to give customers a comfortable experience.

-

Contact

Contact

Welcome to call us for free product quote and relevant corperation.We are pleased to work together with existing client and new client for mutual benefit and common development.